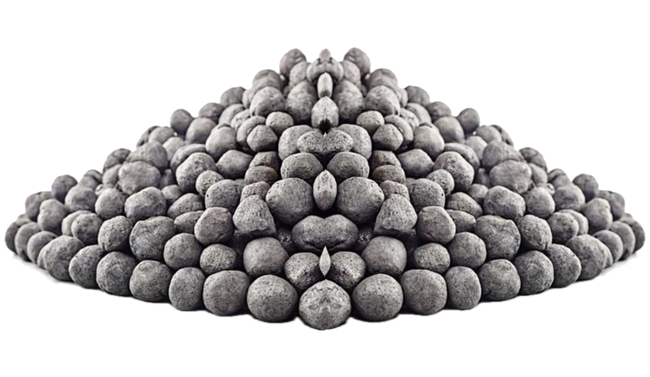

pellet

| Fe (Total) | Min 65% |

| Fe (O) | Max 1% |

| SiO2 | Max 4% |

| CaO | Max 0.7% |

| AL2O3 | 0.07% |

| P | Max 0.05% |

| S | Max 0.08% |

| CCS | Min 250 Kg/Pellet |

| Porosity | 24%-19% |

| Tumble Index | Min 95% |

| Abrasion Index | Max4% |

| Size | 16mm Max 4%< 9-16mm Min 90% 9mm Max 6%> |

| MgO | 0.4% |

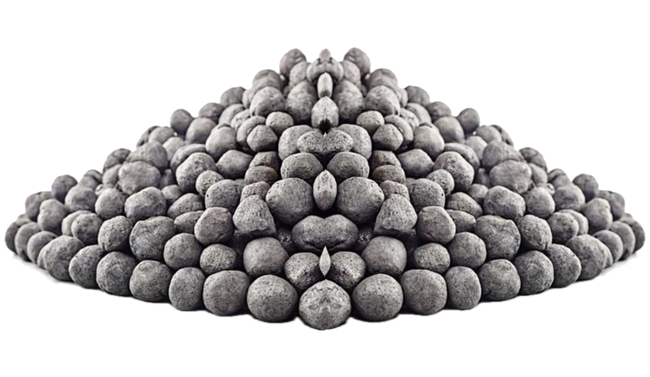

| Fe (Total) | Min 65% |

| Fe (O) | Max 1% |

| SiO2 | Max 4% |

| CaO | Max 0.7% |

| AL2O3 | 0.07% |

| P | Max 0.05% |

| S | Max 0.08% |

| CCS | Min 250 Kg/Pellet |

| Porosity | 24%-19% |

| Tumble Index | Min 95% |

| Abrasion Index | Max4% |

| Size | 16mm Max 4%< 9-16mm Min 90% 9mm Max 6%> |

| MgO | 0.4% |